Wool is a natural fiber from sheep coats. It can be spun into a yarn with qualities that have never been entirely reproduced with manufactured fibers. It is strong and flexible, an excellent insulator, flame resistant, naturally water repellent and also able to absorb up to 50% of its weight in water. The fibers are naturally crimped and springy. The crimping makes the spinning of wool much easier with the fibers naturally binding together. In addition, the microscopic sections or scales along wool fibers allow them to stretch and bend as well as to lock together—giving wool its felting property.

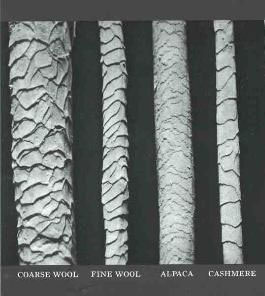

Here are examples of two sheep wool fibers, along with alpaca and cashmere goat fibers, seen under a microscope.

Not all sheep hair is the same—with variations on one animal, from animal to animal, and between breeds. Kemp is the more hair-like portion of a sheep coat, with little or no crimp and of larger diameter and coarser feel. The highest grade of wool is one with the narrowest diameter and with the highest number of crimps in its fiber. Ultra-fine merino wool can have up to 100 crimps per inch.

Here is a photo of a champion merino sheep's coat:

The domestication of wild sheep took place sometime before 6,000 B.C.E., and the earliest wool fleece and fibers positively identified date from about 4,000 B.C.E. We get the name wool from Old English wull, and many other languages base their name for the fiber on the Latin lana.

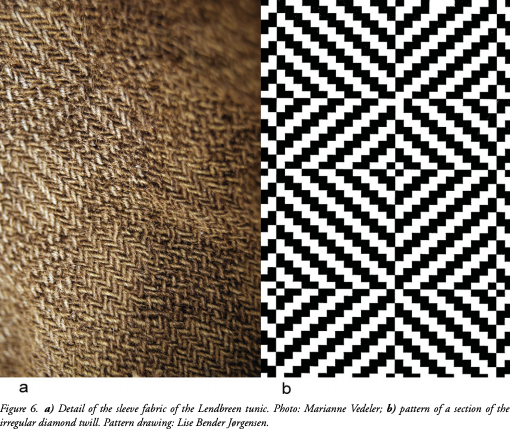

This tunic was discovered in Norway. In remarkable condition from being preserved by glacial ice, it dates from between AD 230 and 390.

It is made of twill weave wool, and it's not even a simple twill!

Wool is obtained from sheep, but the name hair fiber is used to indicate fiber obtained from animals other than sheep.

The animals from which hair fiber is gathered include angora goats (from which we get mohair), cashmere goats (cashmere), angora rabbit (angora), alpaca, camel, and vicuña. More recently the ancient Tibetan craft of spinning yarn from yak fiber (khullu) has become globally known.

Here are some of the things that can be done with wool and hair fiber fabrics:

Felting is a process by which fibers are subjected to heat, moisture and pressure, entangling the fibers into a matted nonwoven fabric. Wool, fur and hair fibers have microscopic scales that give them the ability to interlock and tangle, hence their felting property.

Here's a close-up shot of some dense wool felt used for a hat:

Fulling is a finishing treatment given to wool fabric in which the fabric is subjected to varying degrees of moisture, friction, heat and pressure. This yields a thicker fabric, often with the weave obscured by its felted surface. Almost all wool fabrics are fulled, with winter coat fabrics (such as fleece and melton) fulled most heavily.

A nap is a finish produced on certain woolens, cottons, spun silks and spun rayons involving raising fibers on the fabric. A napper machine has rapidly revolving cylinders covered with fine wire brushes which lift loosely twisted yarns from the fabric to form the nap.

Sheared or cropped fabrics have been trimmed of some or most of their surface fibers in a finishing process. Shearing is almost always done to woolens and worsteds, as well as to many other fabrics. The length of a fabric’s nap is determined by the shearing height.

These processes are really important to know because you may find wool fabrics that don't seem to be woven or knit at all. Felting creates a fabric that is indeed not woven or knit. Fulling and napping can obscure the weave of a fabric.

Here is wool duvetyn. The name duvetyn comes from the French word duvet, meaning down. Wool or wool-blend commonly, the finish is napped, sheared and fulled. This creates a downy nap which covers its weave which is usually right-hand twill.

Sorry to bring up wool when most of us are in the hottest month of the year! I just felt the itch...

Questions? Comments?

Here are examples of two sheep wool fibers, along with alpaca and cashmere goat fibers, seen under a microscope.

Not all sheep hair is the same—with variations on one animal, from animal to animal, and between breeds. Kemp is the more hair-like portion of a sheep coat, with little or no crimp and of larger diameter and coarser feel. The highest grade of wool is one with the narrowest diameter and with the highest number of crimps in its fiber. Ultra-fine merino wool can have up to 100 crimps per inch.

Here is a photo of a champion merino sheep's coat:

The domestication of wild sheep took place sometime before 6,000 B.C.E., and the earliest wool fleece and fibers positively identified date from about 4,000 B.C.E. We get the name wool from Old English wull, and many other languages base their name for the fiber on the Latin lana.

This tunic was discovered in Norway. In remarkable condition from being preserved by glacial ice, it dates from between AD 230 and 390.

It is made of twill weave wool, and it's not even a simple twill!

If you're interested, you can read more about this tunic here: https://www.cambridge.org/core/services/aop-cambridge-core/content/view/S0003598X00049462

Wool is obtained from sheep, but the name hair fiber is used to indicate fiber obtained from animals other than sheep.

The animals from which hair fiber is gathered include angora goats (from which we get mohair), cashmere goats (cashmere), angora rabbit (angora), alpaca, camel, and vicuña. More recently the ancient Tibetan craft of spinning yarn from yak fiber (khullu) has become globally known.

Here are some of the things that can be done with wool and hair fiber fabrics:

Felting is a process by which fibers are subjected to heat, moisture and pressure, entangling the fibers into a matted nonwoven fabric. Wool, fur and hair fibers have microscopic scales that give them the ability to interlock and tangle, hence their felting property.

Here's a close-up shot of some dense wool felt used for a hat:

Fulling is a finishing treatment given to wool fabric in which the fabric is subjected to varying degrees of moisture, friction, heat and pressure. This yields a thicker fabric, often with the weave obscured by its felted surface. Almost all wool fabrics are fulled, with winter coat fabrics (such as fleece and melton) fulled most heavily.

A nap is a finish produced on certain woolens, cottons, spun silks and spun rayons involving raising fibers on the fabric. A napper machine has rapidly revolving cylinders covered with fine wire brushes which lift loosely twisted yarns from the fabric to form the nap.

Sheared or cropped fabrics have been trimmed of some or most of their surface fibers in a finishing process. Shearing is almost always done to woolens and worsteds, as well as to many other fabrics. The length of a fabric’s nap is determined by the shearing height.

These processes are really important to know because you may find wool fabrics that don't seem to be woven or knit at all. Felting creates a fabric that is indeed not woven or knit. Fulling and napping can obscure the weave of a fabric.

Here is wool duvetyn. The name duvetyn comes from the French word duvet, meaning down. Wool or wool-blend commonly, the finish is napped, sheared and fulled. This creates a downy nap which covers its weave which is usually right-hand twill.

Sorry to bring up wool when most of us are in the hottest month of the year! I just felt the itch...

Questions? Comments?

Last edited:

).

).